This post may contain affiliate links, which means that we get commissions for purchases made through such links, at no additional cost to you. As an Amazon Associate we earn from qualifying purchases.

This post contains a simplified step by step guide on how to cure 3D printed resin. Since 3D parts cannot reach their optimum strength without post-curing, it is a very important step that you must master in 3D printing. That was why we have written this post to simplify the process for you.

How do you cure 3D printed resin? You cure 3D printed resin by exposing the 3D printed part to UV light. The different sources of UV light you can use include direct sunlight, UV torches, or special UV curing machines. The light sources also apply some measure of heat to accelerate the curing process. If you are curing under sunlight, submerging the 3D part in water can also make the process faster.

Post-curing may seem complicated at first but it is a very simple process. As you read on, you will learn the nitty-gritty of how to cure 3D printed resin. We will share with you the basic steps of post-curing 3D printed resin. Afterward, we will explain how heat and water can help facilitate the curing of 3D resin prints.

What Are The Steps For Post-Curing 3D Printed Resin?

To effectively post-cure your 3D printed resin, you should get a UV light source. It is preferable to get a standard UV curing machine, and it is better to have a turn-table. These will help facilitate a more effective and even curing. Once these are ready, wash the 3D part in IPA (Isopropyl alcohol), place it in the UV station, apply the right settings, and leave it to cure.

It doesn’t matter how big or small your 3D printed part is, the steps for curing are the same. The only major difference will be how long it would take for the 3D model to fully cure. Thicker and more solid models usually take longer to cure.

Get a UV Light Source

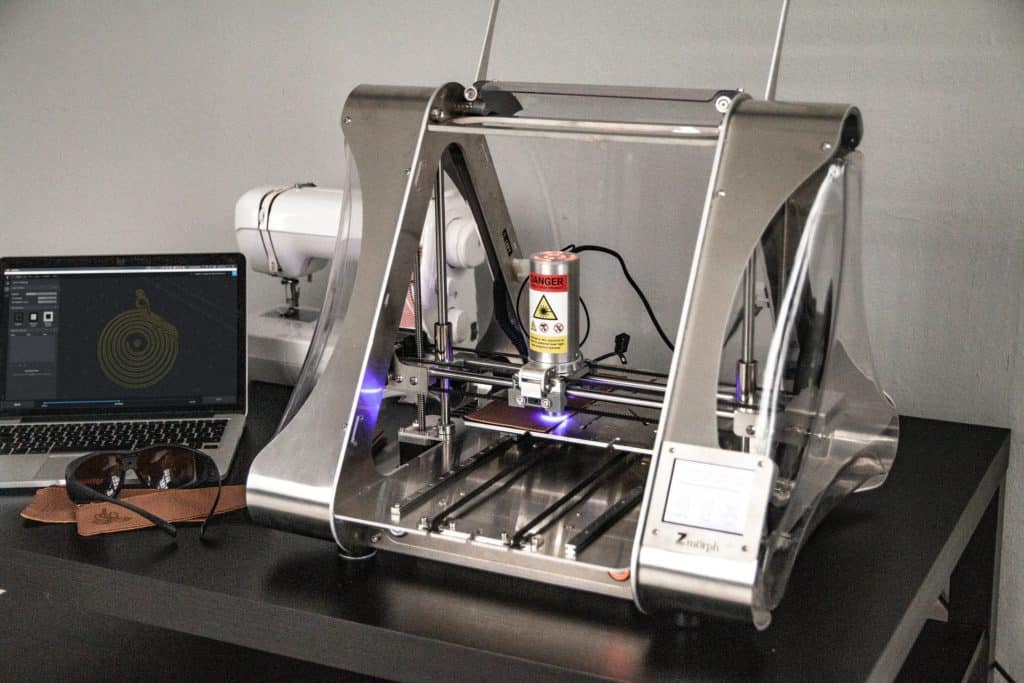

You have quite a few options to choose from. Mainly, there are three options: you can get a ready-made curing solution, make one for yourself, or use sunlight. A professional ready-made station is, however, always the best. An ideal UV curing machine, with appropriate light and heat settings, will give you great results.

UV Curing Machine

If you are looking for a good UV curing machine, you should watch out for the following features:

- Intuitive time control, which allows you to easily regulate the curing time for each model.

- A turntable, which rotates the model while you are post-curing the model. This allows all parts of the 3D printed model to cure evenly as the entire model absorbs UV light evenly.

- Reflective sheet, which reflects the lights within the machine to make the curing effects faster and better.

- A see-through window that allows you to observe and monitor your 3D printed prints curing takes place. The window would also prevent the leakage of UV light.

UV Lamp or Sunlight

If you are using a UV lamp or sunlight, you may need to add a few other items to make the curing process easier and more effective. Some of these items are as follows:

- A turntable, to facilitate even curing. If you are using sunlight, a solar-powered turntable will be ideal.

- A container that will fit both the turntable and the maximum 3D print size you will be curing. Use the base of the turntable as the reference for your measurement.

- Reflective sheet to line the container, so that UV light will bounce around the container for easier, faster, and better curing.

Set Up The UV Curing Apparatus

UV Curing Station

If your 3D printed resin is small, you don’t need a big UV curing machine. A cheap UV nail salon should be good enough. But still, a UV curing station will maximize your 3D resin print’s mechanical properties better. The wavelength for these machines usually ranges from 10 nm to 400nm. Some high-end machines offer a high wavelength of 405 nm.

UV Lamp

If you’re using a UV lamp, mount it in a place where it will aim at the turntable. Then, place your 3D printed resin on the turntable. Leave the setup in place for as long as it takes for the 3D resin to cure fully. You can walk away and return in about 30 minutes to see the results.

Sunlight

If you’re using sunlight, just place the setup under sunlight. You don’t have to mount a UV lamp. Sunlight will also do a good job, but it could be quite slow. What’s more, UV exposure and the effectiveness of curing with sunlight are usually weather-dependent.

✅ Video – How to Post Process Resin Prints

Resin printing and post-processing might seem quite complicated if you don’t have enough understanding of what to do. You will gain valuable insight on how to post-process resin prints from this video. The step to step guide in this video is very simple and easy to follow.

Curing 3D Printed Resin with Heat

Heat alone cannot cure 3D printed resin but it can help accelerate the process. Heat also leads to a more complete and stronger bond formation among resin molecules. It increases the kinetic energy of resin molecules, which means that the molecules will collide and cross-link faster. Combining heat with UV exposure will deliver greater curing results than UV light alone can.

UV light is responsible for the process of polymerization (cross-linking of small molecules to form stronger bonds and a more solid image). But the degree to which polymerization will occur, and the speed with which it will occur, depends on how available the small molecules are for bonding. High heat levels will “agitate” the molecules and make them more available for bonding. This, in turn, accelerates the post-curing process and makes it more effective.

Curing 3D Printed Resin in Water

Some manufacturers advise that you use water for curing. Curing your 3D printed resin in water will prevent oxygen inhibition and allow curing to be more thorough. Oxygen diffuses into resin and greatly slows down curing, but there is less oxygen in water than in air. While water doesn’t have up to 1% oxygen, the air has about 21%.

If you cure your 3D printed resin in water you’ll have less oxygen to contend with and that will make curing faster and more thorough. Submerging your 3D printed model in water will reduce curing time by as much as half. After your 3D print is fully cured, remove it from water and let it dry completely by air. Using heat to dry the 3D model after curing it may cause discoloration.

Related Questions

How Do You Treat 3D Resin Prints?

After printing a resin 3D part, remove the model and chip off any unclean part with a sharp tool. After that, clean the model with isopropyl alcohol (IPA) to remove uncured resin from the printed part’s surface. Then, remove supports using a model cutter and post-cure the model with UV light. Furthermore, you can improve your 3D parts by sanding, priming, polishing, and painting it.

If you don’t clean your 3D resin print appropriately, the surface will have some stickiness or tackiness. Make sure to use enough IPA and make sure the IPA is clean. While removing the supports, be careful not to make a dent in the model.

Do You Need To Cure Resin Prints?

You don’t need to cure all resin prints, but you must cure biocompatible 3D parts. Standard resins, on the other hand, don’t require post-curing. But even if you are printing with standard resins, curing will improve its stability, durability, and strength.

After printing 3D parts with standard resins, they can cure naturally without post-processing them. But it would take more time, and the post-curing results might not be as thorough as if you post-process the model. But biocompatible 3D parts always require post-curing for health and safety reasons.

How Long Does 3D Printing Resin Last?

Unopened 3D UV-sensitive resin can remain intact for many months or years if stored in proper conditions. But if the 3D printing resin is already on your 3D printer tray, it may not last for more than one or two days.

The proper place to store UV-sensitive resin is in a cool dry environment, and away from light. If the resin is already opened, you use a standard orange cover to shield it from UV exposure. Orange covers block reactive UV wavelengths out and prevent UV-polymerization.

Conclusion

So far, we have discussed extensively how to cure 3D printed resin. This post has covered the steps for post-curing, how to set up your UV post-curing apparatus, and what you can do to facilitate a more effective post-curing process. With this information, you should find it very easy to post-cure your 3D printed resin.