This post may contain affiliate links, which means that we get commissions for purchases made through such links, at no additional cost to you. As an Amazon Associate we earn from qualifying purchases.

One of the common questions people ask about 3D printing is, “Do you have to cure 3D prints?” Whenever people talk about 3D printing, they also talk about cleaning and curing. In this post, we are going to be explaining whether this post-curing process is vital for 3D printing or not.

Do you have to cure 3D prints? Curing is compulsory for biocompatible 3D materials but it is not compulsory for Standard Resins. However, curing will still improve the stability and strength of your standard resin 3D prints. You have to cure 3D prints for them to be more stable, stronger, and more durable.

After printing a 3D part, the model remains in a semi-solid (or “green”) state. But when you cure it by exposing it to the appropriate UV wavelength and heat, it becomes more solid and takes on a more stable physical form. Read on to find out more about post-curing 3D prints.

Why Do You Have To Cure 3D Prints?

Resin, which is used for 3D printing, is a syrup-like liquid that hardens under UV light exposure. If you don’t expose resin to the appropriate UV light wavelength, it will not be fully formed. More so, resin printers print 3D objects layer by layer. Each layer is practically distinct after printing, but post-curing interlinks them together to form one whole solid image.

Resins will still harden without UV light exposure, although at a very slow pace. But UV light makes each layer of resin bond with the subsequent layer. So as each layer hardens, they do not harden as distinct layers, but as a solid model.

What UV curing does is to complete the polymerization of bonds in resin materials. This means that when you cure 3D resins, the small molecules in them begin to link together. So, they form a chain-like network of larger molecules that are harder to break apart. What’s more, post-curing makes sanding and painting 3D parts easier. This, in turn, allows for a smoother and more detailed finish.

How Do You Cure 3D Prints?

You can cure 3D prints in three easy steps. First, remove the 3D part from the printing platform, wash it with IPA, and place it under UV light for post-curing. You may choose to use sunlight, a regular UV lamp, or a specialized UV station. After fully curing your 3D print, its mechanical and functional properties improve and it attains its best possible strength.

To post-cure your 3D print, you need the following items.

- UV light

- 91% IPA (Isopropyl Alcohol) or 99% Rubbing Alcohol

- A squeeze bottle or large container (big enough to fully submerge your 3D print)

- Disposable gloves

- One pair of pliers

You can easily purchase all of these items over the counter. And you can use this simple post-curing setup for diverse 3D print applications. This includes 3D parts for jewelry, cosplay, prototypes, or miniatures. The section below explains three easy steps for curing 3D prints.

Clean the 3D Print with IPA

Start by removing the model from the printing platform with a sharp tool. After removing the print, submerge it in an IPA-filled container for about 3 minutes. Spin the model around a bit to make the cleaning process more effective.

In place of using an IPA-filled container, you can also use an IPA-filled squeeze bottle. Squeeze IPA from the squeeze bottle onto your 3D print to remove extra resins. Whether you use a large container or squeeze bottle, the important thing is to remove uncured resins. This reduces residual stickiness from the surface of your 3D model.

Remove Printing Supports

After cleaning the model, gently remove printing supports from the model using a cutter. The best place to start is the area around the tips since printing supports are usually pointed. Just be careful not to make a dent in the model while removing the supports. To be safe, you can leave a little bit of protruding tip and sand it down afterward.

Cure with UV Light

You can use either direct sunlight or a post-curing UV lamp to cure your 3D printed part. However, it is easier to regulate the setting if you are using a UV lamp or station. You can’t control the settings if you are using direct sunlight. The level of heat and UV light you get from sunlight usually depends on the weather condition per time.

Besides, sunlight can take a longer time to cure resin prints than UV light stations. But other factors, such as model size and resin type also affect the duration of post-curing. Submerging the print inside a clear container filled with water during this final step can also make curing faster. This is, however, optional.

✅ Video – Resin Prints – From Print to Cure – Tips and Tricks

Did you know that your 3D model can become opaque if you wash with another solution, other than IPA? In this comprehensive video, Dirk Herrendoerfer shares valuable tips on how to post-process your 3D prints. The explanation starts from the point when print ends to the stage of leaving the model under UV-light to cure. Watch this video for more tips and tricks on post-processing resin prints.

The Use of Heat and IPA Solution While Curing 3D Prints

You need UV light to unlock your 3D parts’ full potential. But you may also need heat to make the process faster. Heat mobilizes the molecules in resin and further facilitates the post-curing process. So your 3D print will be fully cured faster and better than when you use UV light alone. Each resin type, however, requires different UV post-curing heat and light settings.

Before curing your 3D printed part, you will have to rinse away any excess uncured resin. For this, you need a solvent. And IPA (isopropyl alcohol) happens to be the choice solvent for cleaning 3D prints to remove excess resin.

The cleaning process makes the 3D printed part perfectly clean if done properly. If the model is not clean enough, the surface will be somewhat sticky. This can happen if you don’t use enough IPA or if you use a contaminated IPA.

How Does Water Reduce Curing Time?

Oxygen usually diffuses from the atmosphere into resins during printing. If this occurs again during curing, it can slow down the post-curing process. Submerging 3D prints inside water while curing them forms a barrier that prevents oxygen from inhibiting the curing process. This water barrier allows light from a UV lamp or the sun to cure 3D prints faster.

Post-curing a 3D print without placing it in water will require a longer time. While the surface layer of the 3D might cure fully, interior structures may not cure well enough. Over time, however, ambient light will continue curing the interior structures gradually.

Related Questions

Is 3D Printing Useful?

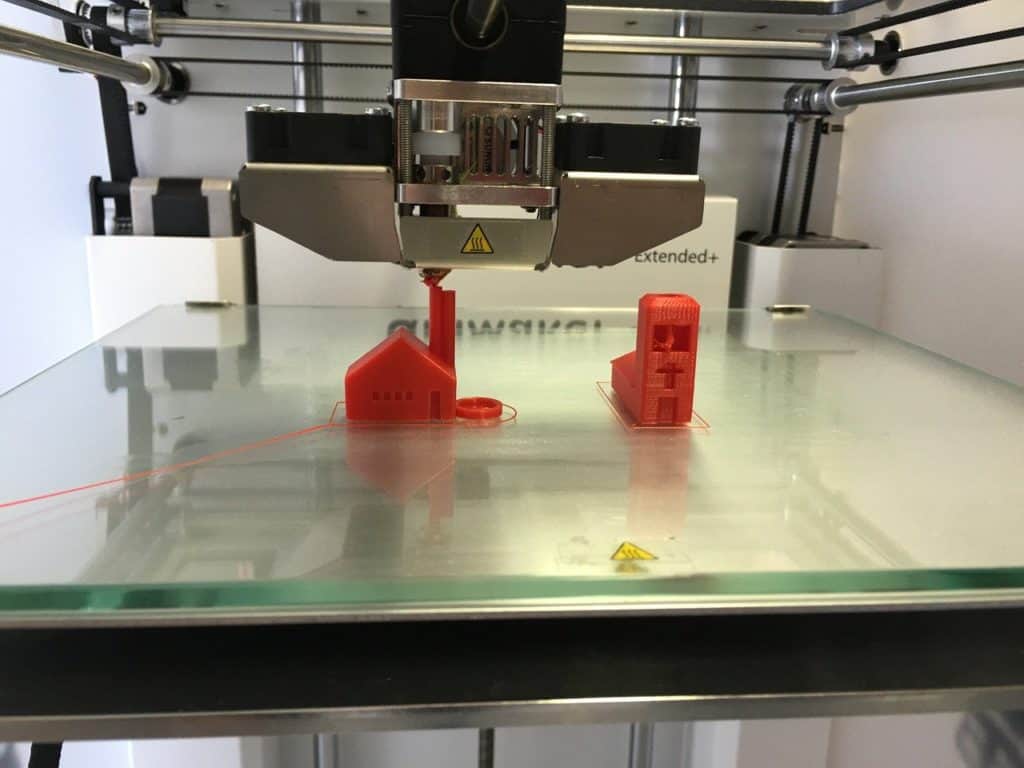

3D printing is useful for many fields, including medicine, fashion, and architecture, among other fields. You can use this technology to make prosthetics, jewelry, cosplays, and diverse kinds of prototype models. Examples of prototype models you can make with 3D printers include housing prototypes, as well as realistic prototypes for surgical training aids.

These are only a few examples of what you can do with 3D printing. You can create various personalized items with this amazing technology. Even the automotive and engineering industries use 3D technology to make rapid prototypes for their products. 3D printing offers a brighter future for manufacturing and many other industries. Thankfully, 3D technology is developing further and becoming more available.

Can You Over-Cure Resin Prints?

You can over-cure resin prints if you leave it under UV light for too long. If this happens, the resin print will become brittle and susceptible to easy breakage. However, over-curing will eventually happen since UV resin remains reactive to UV light even after you have finished the curing process. However, ambient light will take months or even years to damage your resin print if you take the necessary cautions.

You should not leave your resin print at the window or under exposure to direct sunlight. If you do, the UV light will break it down and cause easy damage. This happens with every organic material and not just resin alone. All organic materials degrade from intense or extended UV exposure.

What Are The Cons Of 3D Printing?

One of the major disadvantages of 3D printing is that there are limited materials you can use. This is because only a few materials can be controlled well enough by temperature to support 3D printing. More so, some 3D printable materials are not safe for consumption and some are not recyclable. Size restriction is another drawback with 3D printing. The size of 3D printing chambers limits the size of 3D parts you can print with them.

Conclusion

As we have discussed, some 3D prints, like biocompatible materials, need curing while some do not. While standard resin can cure without UV light, UV lights will make the process faster and more effective. Don’t forget to wash your 3D part with IPA before curing it, and remember to submerge the part in water during curing. What’s more, appropriate heal levels can also help with the post-curing process.